The Town of Waterford, CT was incorporated in 1801 to become the 109th Town in the State of Connecticut. The Town currently has a population of 19,700. Bordering the Niantic River, Waterford has 23 miles of coastline with a land area of 37.9 square miles. Waterford’s collection system was completed in the 1980’s using PVC pipes and precast manholes. Wastewater from Waterford is treated at the neighboring town of New London’s wastewater treatment plant. It is metered and then paid for by the town. In the 2012 fiscal year it was reported that Waterford residents only used 402,713,000 gallons of water but 553,391,680 gallons were sent to the plant. This means that 27% of the total amount of water came from infiltration or from unnecessary inflow.

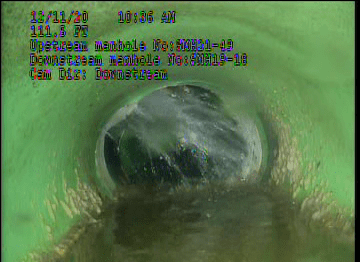

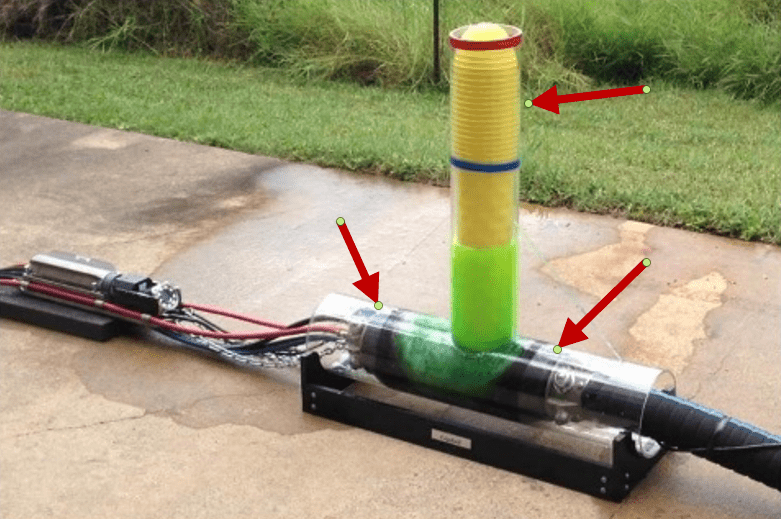

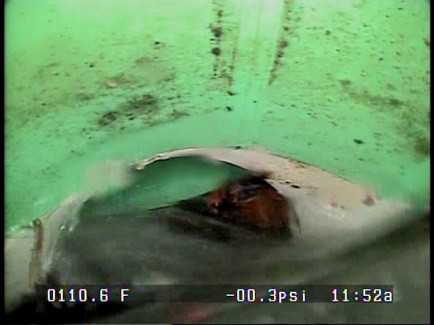

Waterford’s Utility department regularly inspects the collection system for defects/issues and to comply with CMOM regulations. Upon inspecting the pipelines, several major leaks at the intersection where lateral pipes were connected to the mainline sewer were observed. After identifying 14 laterals were leaking substantially, it was determined that most of the laterals had infiltration of at least 4 gallons per minute, equating to 29,433,600 gallons per year or roughly $136,000/year in treatment cost for the excess water added to their system. Looking for a permanent solution to this costly problem, Waterford’s Utility department turned to sewer grouting. The sealing of laterals and the lateral connections to the sewer main to eliminate groundwater infiltration is achieved through the process of sewer grouting. Mainline sewer grouting has been around for over 60 years and lateral grouting has been around for nearly 30 years. Both are an effective tool for stopping groundwater infiltration into manholes, joints, and lateral connections. A lateral packer is a specialized piece of equipment consisting of three elements; two end bladders that are inflated on each side of the lateral creating a seal to the mainline, and a third bladder or tube that is sent up the lateral which creates a third seal at the end of the bladder. Once all three areas of the packer are seated against the pipe and lateral, the lateral can be air pressure tested. If it fails the air test, grout is then pumped through the open joints or defects and flows outside of the pipe into the surrounding backfill where it solidifies (or gels), creating a positive seal on the exterior of the pipe. Once grouted, the joints are then retested to confirm the seal.

Tree-way seal used to test lateral connections

The project was completed by Green Mountain Pipeline Services in September 2021 and took only 3 days to seal the 14 laterals. The town of Waterford cleaned and televised the sewer lines prior to the grouting operation commencing. This also helped to lower the overall cost by performing the work in-house. 84 gallons of American Chemical Grout Co. ACG-AG acrylamide grout were used to completely stop the infiltration, eliminating not just the excess water, but also the needless spending for the additional water to be treated at the plant.

Why is injection grouting so effective at stopping infiltration? The answer simply lies in the materials and techniques utilized. The process of grouting consists of injecting two water-based component chemicals through an open joint or defect. When the two liquids meet, a chain reaction occurs resulting in an inert gel that is installed on the outside of the pipe. This “gel” time is controllable and is set based upon the amount of material placement required for the diameter of the pipe, the length of the lateral bladder, and the pumping rate. As the liquid grout exits the open joint or defect it immediately drops below the pipe. This helps to reestablish pipe stabilization by creating a cradle underneath while filling any voided areas around the pipe. The grout then forms a seal around the defect and combines with the surrounding backfill, creating a gel/soil matrix that reinforces the seal. During grouting operations, operators closely monitor the pressure and the amount of grout pumped. This helps to assure that the proper amount of grout is placed. NASSCO’s Infiltration Control Grouting Committee (ICGC) has just published 2 new specifications for sewer grouting. To download the newly released specifications for Capital Grouting and Pre-Rehabilitation Grouting go to www.NASSCO.org. MORE ABOUT GREEN MOUNTAIN PIPELINE SERVICES Founded in 2003, Green Mountain Pipeline Services offers a wide range of pipeline inspection and rehabilitation services using trenchless technology. This includes closed circuit TV inspection of mainlines and laterals; cured-in-place pipe (CIPP) mainline and lateral lining; trenchless spot repairs; grouting of mainlines, manholes and laterals; manhole/structure cementitious lining and reconstruction, with epoxy as needed; pipeline/structure cleaning and vacuuming; and smoke testing, manhole inspections, dye testing and flow isolation. Headquartered at 768 South Main Street, Unit 1, in Bethel, Vermont, GMPS is a subsidiary of Infrastructure Services Group LLC, which acquires and funds profitable and well-positioned private companies that specialize in water and wastewater pipeline and manhole inspection, maintenance and rehabilitation.